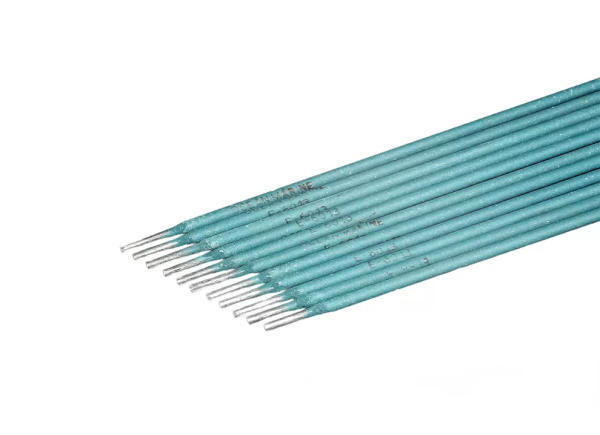

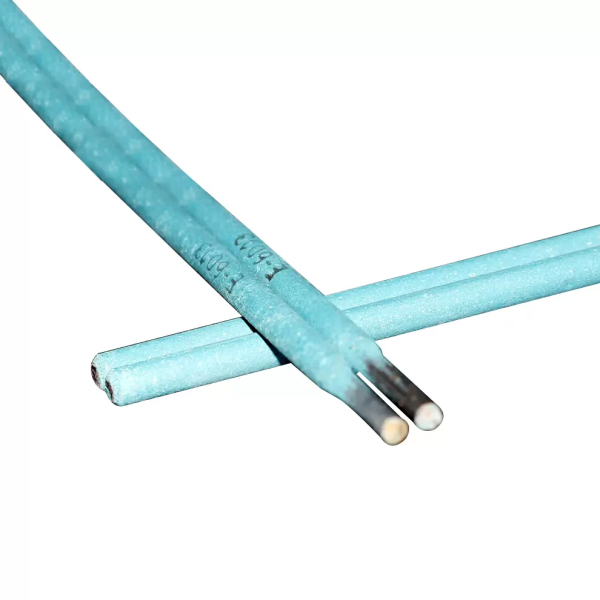

J421 Welding Electrode

J421 is a carbon steel welding rod with rutile coating. It can be used for both AC and DC, and can be used for all-position welding. It has excellent welding process performance, good operating performance, easy arc ignition, stable arc, and beautiful welding seam shape.

Email: [email protected]

Share to:

Chemical composition of deposited metal

| Project | C | Mn | Si | S | P | Ni | Cr | Mo | V |

| Guaranteed value | ≤0.20 | ≤1.20 | ≤1.00 | ≤0.030 | ≤0.035 | ≤0.30 | ≤0.20 | ≤0.30 | ≤0.08 |

| Example | 0.08 | 0.40 | 0.20 | 0.020 | 0.025 | 0.030 | 0.035 | 0.005 | 0.004 |

Mechanical properties of deposited metal

| Project | Tensile strengthRm/MPa | Yield StrengthRel/Rp0.2 MPa | ElongationA(%) | Charpy V-notch impact absorption energyKV2(J) |

| 0℃ | ||||

| Guaranteed value | ≥430 | ≥330 | ≥16 | ≥47 |

| Example | 485 | 430 | 28 | 70 |

Reference current

| Welding diameter(mm) | Φ2.5 | Φ3.2 | Φ4.0 | Φ5.0 |

| Welding length(mm) | 300 | 350 | 400 | 400 |

| Welding current(A) | 50~90 | 90~130 | 150~200 | 180~250 |

Features:

J421 is a carbon steel welding rod with rutile coating. It can be used for both AC and DC, and can be used for all-position welding. It has excellent welding process performance, good operating performance, easy arc ignition, stable arc, and beautiful welding seam shape.

Usage:

Welding low carbon steel structures, especially suitable for thin plate small parts and cover welding that require beautiful and smooth weld surfaces.

Precautions:

Under normal circumstances, the electrode does not need to be baked before welding. When the electrode gets wet, it must be baked at 150-170°C for 0.5-1 hour before use.